Building

Fabric O&M Information

Building

Fabric O&M Information

Demo Project

123 Test Road

Hastings

East Sussex

TN38 9UH

Start Date: 01/01/2025

End Date 01/01/2025

Manuals Compiled by

Manuals Compiled by

Contents of Building Fabric Section

Navigation hints

· You should have a ‘Document Map’ to the left of this page. If it is not showing go to the ‘View’ tab on the Word ribbon, and ensure that ‘Navigation Pane’ is ticked in the ‘Show’ section.

· The headings listed in the Document Map on the left link to the correct part of the document - simply click on the heading in which you are interested.

· The Content list below also links with a click.

· Throughout this document there are links to other separate documents – these are marked as blue and underlined. When clicking on these links the new document will be opened leaving the current document open underneath.

Contents of Building Fabric Section

3.2. Carpets and Stair Nosings

3.4. Fabrication – Including Terrace Fence, Balustrade and Staircase Modification

3.6. Glazing including New Roof Light

3.8. Manhole Covers and Frames

1. Introduction

The purpose of this manual is to offer the personnel concerned with the operation and maintenance of the services within the building, maximum assistance in the performance of their duties. It is intended that this manual will be used to assist skilled engineers, experienced in the operation and maintenance of building fabric and associated systems and to provide them with a working knowledge of the various systems installed within the project.

All information contained herein is valid at the time of preparation and the date of issue. Changes arising in building usage, legislation etc. will necessitate revisions to be made in order to retain the manuals validity and usefulness. Any such revisions should be recorded in the Health & Safety File – Amendment Record Sheet

It should be noted that this manual is not intended to supersede or conflict with any standard maintenance/inspection routines already in use for the base build system.

2. List of Abbreviations

|

A |

Ampere |

|

A/V |

Audio/Visual |

|

AAV |

Automatic Air Vent |

|

AC |

Alternating Current |

|

ACOP |

Approved Code of Practice |

|

|

|

|

BCWS |

Boosted Cold Water Service |

|

BEMS |

Building Energy Management System |

|

BHWS |

Boosted Hot Water Service |

|

BIM |

Building Information Modelling |

|

BS |

British Standard |

|

|

|

|

CAD |

Computer Assisted Design |

|

CATV |

Cable Television |

|

CCTV |

Closed Circuit Television |

|

CD |

Compact Disk |

|

CD-ROM |

Compact Disk - Read Only Memory |

|

CDM |

Construction, Design and Management |

|

CFC |

Chlorofluorocarbon |

|

CFM |

Cubic Feet Per Minute |

|

CIBSE |

Chartered Institution of Building Services Engineers |

|

COAX |

Co-Axial |

|

COSHH |

Control of Substances Hazardous to Health |

|

CPU |

Central Processing Unit |

|

CT |

Constant Temperature |

|

CWS |

Cold Water Service |

|

CMDS |

Cold Water Down Service |

|

|

|

|

dB |

Decibel |

|

DC |

Direct Current |

|

DDC |

Direct Digital Control |

|

DCV |

Double Check Valve |

|

DMM |

Digital Multi-meter |

|

DRV |

Double Regulating Valve |

|

DVM |

Digital Voltmeter |

|

DWG |

Autocad Drawing Format |

|

DXF |

Drawing Exchange Format -Autocad DXF |

|

|

|

|

ELCB |

Earth Leakage Circuit Breaker |

|

EMC |

Electromagnetic Compatibility |

|

EMI |

Electromagnetic Interference |

|

ESD |

Electrostatic Sensitive Device |

|

|

|

|

F |

Flow |

|

F&E |

Feed and Expansion |

|

FA |

From Above |

|

FB |

From Below |

|

FD |

Fire Damper |

|

FFL |

Finished Floor Level |

|

FM |

Frequency Modulation |

|

FMV |

Flow Measurement Valve |

|

FODRV |

Fixed Orifice Double Regulating Valve |

|

|

|

|

GRP |

Glass Reinforced Polyester |

|

|

|

|

HCFC |

Hydrochlorofluorocarbon |

|

HL |

High Level |

|

HOFR |

Heat Resisting, Oil Resisting and Flame Retardant |

|

HRC |

High Rupture Capacity |

|

HSE |

Health and Safety Executive |

|

HTG |

Heating |

|

HV |

High Voltage |

|

HVAC |

Heating Ventilating and Air Conditioning |

|

HVCA |

Heating and Ventilating Contractors Association |

|

HWS |

Hot Water Service |

|

HZ |

Hertz (Cycles Per Second) |

|

|

|

|

IET |

The Institution of Engineering and Technology |

|

IV |

Isolating Valve |

|

|

|

|

K |

Kilo (1000 Units) |

|

KA |

Kiloampere (1000a) |

|

KHZ |

Kilo Hertz (1000 Cycles Per Second) |

|

KVA |

Kilo Volt Amperes |

|

KWH |

Kilo Watt Hours |

|

|

|

|

LED |

Light Emitting Diode |

|

LCD |

Liquid Crystal Display |

|

LL |

Low Level |

|

LPHW |

Low Pressure Hot Water |

|

LPV |

Lubricated Plug Valve |

|

LSV |

Lock Shield Valve |

|

LV |

Low Voltage |

|

|

|

|

M |

Metre |

|

MCB |

Miniature Circuit Breaker |

|

MCCB |

Moulded Case Circuit Breaker |

|

MICC |

Mineral Insulated Copper Cable |

|

MM |

Milli-Metre(S) |

|

MPHW |

Medium Pressure Hot Water |

|

MUX |

Multiplexer |

|

MWS |

Mains Water Service |

|

|

|

|

N |

Newton |

|

NICAD |

Nickel Cadmium (Rechargeable Battery) |

|

NICEIC |

National Inspection Council for Electrical Installation Contracting |

|

NRV |

Non-Return Valve |

|

|

|

|

OEL |

Occupational Exposure Level |

|

OV |

Open Vent |

|

|

|

|

PA |

Pascal |

|

PCB |

Polychlorinated Biphenyl |

|

|

Portable Document Files |

|

PE |

Polyethylene |

|

PF |

Power Factor |

|

PFC |

Power Factor Correction |

|

Ph |

Phase |

|

PIR |

Passive Infra-Red |

|

PP |

Polypropylene |

|

PTFE |

Polytetrafluoroethylene |

|

PVC |

Polyvinylchloride |

|

|

|

|

RCBO |

Residual Current Breaker |

|

RCCB |

Residual Current Circuit Breaker |

|

RCD |

Residual Current Device |

|

RH |

Relative Humidity |

|

RIBA |

Royal Institute of British Architects |

|

RICS |

Royal Institution of Chartered Surveyors |

|

RMS |

Root Mean Square |

|

RPM |

Revolutions Per Minute |

|

|

|

|

SPN |

Single Pole & Neutral |

|

STP |

Shielded Twisted Pair |

|

SWA |

Galvanised Steel Wire Armour |

|

SV |

Safety Valve |

|

|

|

|

TA |

To Above |

|

TB |

To Below |

|

TP |

Test Point |

|

TPN |

Three Phase & Neutral |

|

TRV |

Thermostatic Radiator Valve |

|

|

|

|

UPS |

Uninterruptible Power Supply |

|

UTP |

Unshielded Twisted Pair (Wire Cable) |

|

uPVC |

Un-plasticised Polyvinylchloride |

|

UV |

Ultra Violet |

|

|

|

|

V |

Volt |

|

VA |

Volt Ampere |

|

VAV |

Variable Air Volume |

|

VCD |

Volume Control Damper |

|

VIR |

Vulcanised Indian Rubber |

|

VRV |

Variable Refrigerant Volume |

|

|

|

|

W |

Watt |

|

|

|

|

XLPE |

Cross-Linked Polyethylene Insulated |

3. Building Fabric Elements

3.1. Acoustic Plant Enclosure

3.1.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.1.2. Scope of Works

Company Name was responsible for the supply and installation of an acoustic panel work screen.

Acoustic panelwork is fabricated from pre-galvanised sheet steel, solid outer face and perforated inner face. Internal stiffeners are either spot welded or riveted at nominal 600mm centres. The acoustic infil is inorganic mineral wool infil.

Door frames are fabricated from 50 x 100 RHS steel to all four sides with welded corners. The frame and leaf are drilled and tapped to accept the fixing screws. Acoustic door leaves are fabricated from pre-galvanised sheet steel, with internal tapping bars for hinges and door furniture. Doors are fitted with neoprene seals; standard slam latches with internal panic release strike and heavy duty strap hinges.

3.1.3. Care and Maintenance

3.1.3.1. Acoustic panel work and doors

Composition

The products are fabricated from pre-galvanised sheet steel (door frames mild steel box section)

Optional Extras

Polyester powder paint finish to the external surfaces.

Cleaning Instructions and Frequency of Cleaning

Non-alkaline detergent and warm water may be safely applied to the finish using a soft cloth or sponge, and nothing harsher than a bristle brush should be used. If there is any doubt, a few moments invested in testing the cleaner on an unobtrusive area of the louvre will prevent a major problem. The cleaner should be in the same concentration and be applied in the manner intended for the job. The finish should be inspected for stains or for softening or dissolution of the organic finishes after the cleaner has dried.

Steel wool, strong acids, alkalis and abrasive cleaners must never be used.

The accumulation of atmospheric grime and pollution makes it necessary to clean the surface regularly to maintain its good appearance. In badly polluted industrial, marine or large city locations it is recommended that cleaning be carried out once every three months and in relatively cleaner rural locations once every six months.

This frequency will also depend upon the standard of appearance that is required. Provided this recommended frequency be maintained, it should never be necessary to use cleaners which are more aggressive than a non-alkaline detergent in warm water concentrations which can be handled with bare hands.

After application these cleaners should be removed with clean water and the area wiped dry.

Inspection Frequency

It is recommended that inspection be carried out during cleaning.

Fixings (where visible) should be inspected annually for corrosion and to ensure they have not worked loose. Fixings should be replaced or retightened as necessary.

Maintenance Frequency

It is recommended that light oiling of the hinges, locks, and bolts be applied to the doors at no more than three to six monthly intervals. Where fitted, seals should be inspected for damage and replaced if necessary.

Expected Life and/or Period Recommended Before Replacement.

After an extended period of time, the length of which is dependant on the environment and efficiency of routine cleaning, but which would probably be in excess of ten years for architectural grade polyester powder, it may be aesthetically desirable to refinish the surface. A two pack material is available and can be applied “in-situ”.

The expected life of the louvre should be, if properly maintained, for 10 to 15 years. An exception is moving parts on door furniture, which will require replacement according to the amount of usage involved.

3.1.4. Health & Safety

When subject to the normal purposes for which they are designed, these products do not present a health risk. These products may have sharp edges or corners and the use of gloves is recommended when handling.

The fabricated items are not considered a fire hazard.

Metal is a good conductor of electricity and precautions should be taken to ensure contact with live power lines is avoided.

Aluminium in a finely divided form, i.e. powder or dust, has specific safety problems not encountered with the metal in the massive form. Specialist advice should be sought if the products are to be cut with grinders, welded or polishing.

3.1.4.1. COSHH

SUBSTANCE

Inorganic Mineral Wool

NAME AND ADDRESS OF MANUFACTURER/SUPPLIER

Knauf Insulation Ltd,

PO Box 10, St Helens,

WA10 3NS.

Tel: 01744 766600

OCCUPATIONAL EXPOSURE LIMIT OF SUBSTANCE (WHERE APPLICABLE)

Fibres maximum exposure limit 5mg/m 3

MATERIAL CLASSIFICATION

IRRITANT YES

TOXIC NO

CORROSIVE NO

HARMFUL NO

FLAMMABLE NO

HIGHLY FLAMMABLE NO

LOCATION WHERE SUBSTANCE IS USED

Fitted inside acoustic lining

RECOMMENDATION FOR USE OF SUBSTANCE

No special precautions

RECOMMENDATION FOR STORING SUBSTANCE

Store in packing until it is to be used

RECOMMENDATION FOR CLEARING SPILLAGE

Spray area with water before sweeping

RECOMMENDATION DISPOSAL:

No special precautions, not classified as special waste

No known adverse environmental effects

European waste catalogue code 17 06 04

TRANSPORT INFORMATION

Not classified for transport.

EMERGENCY ACTION TO BE TAKEN IF EXPOSED TO SUBSTANCE:

Skin Contact

If irritation occurs, wash under cold running water prior to using soap. Do not scratch or rub.

Eyes

Flush with cold potable water.

Ingestion

Drink plenty of cold water. If symptoms persist, seek medical attention immediately.

Inhalation

If eye or respiratory irritation occurs, leave area to get fresh air.

If symptoms persist, seek medical attention immediately.

MAIN CONSTITUENTS OF SUBSTANCE:

Mineral wool man (machine) made vitreous fibre (mmvf), alkali and alkaline earth (CaO + MgO + NaO + K2O) > 18 % in weight meeting the requirements of Note Q of directive 97/69/EEC

ASSESSMENT OF RISK IN USING THIS SUBSTANCE

LOW

SAFETY EQUIPMENT TO BE USED

Hand protection

Not normally required but gloves should be worn and any exposed skin covered

Eyes

With heavy dust or working in unventilated areas, disposable face mask should be worn and goggles recommended.

FIRE-FIGHTING MEASURES

Product is non-combustible. Any type of fire extinguisher suitable

For further details refer to Knauf insulation Safety Data Sheet KI_DP_201 dated 06 Feb 2014

REPORT COMPILED BY

Brian Kirby, contracts manager DATE: 17 Sep 2014

3.1.5. Residual Risks

|

Activity |

Hazard |

Risk |

Control Measures |

|

Access to louvres at high level for cleaning and inspection |

Fall from height

Falling tools & materials |

Low

Low to Medium |

Provide correct access equipment; i.e. scaffold or boom lift. Ensure person is competent and training for use of equipment Fall arrest equipment may be required depending upon the means of access. Cordon off area below working area. |

|

Maintenance of doors |

Small hand tools |

Low |

Ensure person is competent and trained. Appropriate PPE (e.g. goggles and gloves) for tools selected. |

3.1.6. Warranties

Guarantee & Life Expectancy

The Company warrants all equipment manufactured by it to be free from defects from workmanship or material under normal use and service. If any part of the equipment sold by the Company proves to be defective in workmanship or material and subject to the Company’s prior permission in writing, if such part is within 12 months from the date of dispatch from the Company’s Factory returned to such Factory, carriage paid, and if the same is found by the Company to be defective in workmanship and material it will be replaced or repaired free of charge (Ex Works). The Company assumes no liability for consequential damages of any kind and the Customer, by acceptance of this equipment, would assume all liability, for the consequences of its use or misuse by the Customer, his Employees or others. A defect in the meaning of this warranty in any part of said equipment shall not, when such part is capable of being renewed, repaired or replaced, operate to condemn such equipment. This warranty is expressly in lieu of all other warranties, guarantees, obligations or liabilities expressed or implied by the Company or its representatives.

Paint Finish

The outer faces of the panelwork and louvres are painted with a two pack acrylic paint finish with a two pack etch primer. Finished colour RAL 7042 grey.

Expected Life and/or Period Recommended Before Replacement

After an extended period of time, the length of which is dependent on the environment and efficiency of routine cleaning, but which would probably be in excess of ten years for architectural grade polyester powder, it may be aesthetically desirable to refinish the surface. A two-pack material is available and can be applied “in-situ”.

The expected life of the panels should be, if properly maintained, ten to fifteen years. An exception is moving parts on door furniture, which will require replacement according to the amount of usage involved.

3.1.7. Recommended Spares

Items are passive components with the exception of hinges and door latches/locks, have no moving parts. Each item has been made in sizes specifically for the project. No spares are kept in stock but replacement parts may be available.

3.1.8. Manufacturers Information

|

1. Description of Item |

Acoustic Screen |

|

Manufacturer Contact details |

Noico Patrick House Station Road Hook RG27 9HU

Tel: 01256 766207 Fax: 01256 768413 |

|

Manufacturers Literature |

As per Record Drawing |

3.1.9. Test and Commissioning Certificates

Direct to Client

3.1.10. Record Drawings

|

Drawing Number |

Drawing Title |

Rev |

Issue Date |

Checked |

|

01 |

A |

17/03/2016 |

- |

3.2. Carpets and Stair Nosings

3.2.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.2.2. Scope of Works

Company Name was responsible for Supply & Installation of Floorcoverings comprising:

New carpet tiles & stair nosings to the Main Staircase Ground to 5th Floor

New stair nosings to the Rear External Staircase Lower Ground to 5th Floor

New metal frame matting to Entrance Matwell

3.2.3. Care and Maintenance

Refer to manufacturers literature attached within section 5.2.7 of this manual

3.2.4. Health & Safety

N/A

3.2.5. Warranties

Click to view Interface Warranty Document

3.2.6. Recommended Spares

N/A

3.2.7. Manufacturers Information

|

1. Description of Item |

Interface Composure Carpet Tiles |

|

Colour/Code/Ref/Batch number/ |

Diffuse 303002 |

|

Location |

Main Staircase Ground to 5th Floor |

|

Manufacturer Contact details |

Interface Europe Limited Shelf Mills Halifax West Yorks HX3 7PA

Tel: 01274 690690 Fax: 01274 694095 |

|

Manufacturers Literature |

|

2. Description of Item |

Gradus G32 Stair Nosings |

|

Colour/Code/Ref/Batch number/ |

As above Black Inserts |

|

Location |

Main Staircase Ground to 5th Floor |

|

Manufacturer Contact details |

Gradus Accessories Chapel Mill Park Green Macclesfield Cheshire SK11 7LZ

Tel: 01625 428922 Fax: 01625 433949 Web: www.gradusworld.com |

|

Manufacturers Literature |

|

3. Description of Item |

Safety Buyer Talon Grip Stair Nosings |

|

Colour/Code/Ref/Batch number/ |

As above colour Yellow |

|

Location |

Rear Staircase Lower Ground to 5th Floor |

|

Manufacturer Contact details |

Safety Buyer UK Limited Newton Business Park Talbot Road, Hyde Cheshire SK14 4UQ

Tel: 0800 0430161 Fax: 0161 3123345 Web: www.safetybuyer.com |

|

Manufacturers Literature |

- |

|

4. Description of Item |

Forbo Connect Matting |

|

Colour/Code/Ref/Batch number/ |

As above with Coral Classic Inserts |

|

Location |

Entrance Matwell |

|

Manufacturer Contact details |

Forbo Flooring UK Ltd PO Box 1 Kirkcaldy KY1 2SB

Tel: 0870 8550 500 Fax: 0870 8550 535 Email: info.flooring.uk@forbo.com |

|

Manufacturers Literature |

3.2.8. Test and Commissioning Certificates

N/A

3.2.9. Record Drawings

N/A

3.3. Decoration

3.3.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.3.2. Scope of Works

Existing Walls & Ceilings / New Ceilings (General)

Painted - Dulux Vinyl Matt Emulsion

Reference - RAL 9010

New & Existing Skirting / Existing Doors & Frames / Internal Balustrade

Painted - Dulux Satinwood

Reference - RAL 9010

Existing Corridor Ceiling (Lower Ground)

Painted - Armstead Vinyl Matt Emulsion

Reference - Black

Shower Walls & Ceilings (Basement)

Painted - Dulux Vinyl Silk

Reference - RAL 9010

Front Elevation

(Treated with StoPrim Fungal & primed with StoPlex W)

Painted - StoColor Silco

Reference - Colour 31135

Front Elevation - Balustrade

Painted - Dulux Gloss

Reference - Black

Rear Elevation

Painted - Dulux Weather Shield Smooth Masonry

Reference - 60YY 65/082

Rear Fire Escape Stairwell - Handrail

Painted - Dulux Gloss

Reference - Black

Rear Fire Escape Stairwell – Concrete Ceiling

Painted - Dulux Weather Shield Smooth Masonry

Reference - White

Rear Fire Escape Stairwell – Doors & Frames

Painted - Dulux Gloss

Reference - White

Exterior Metalwork – Roof & Front

Painted - Dulux MetalShield Satin

Reference - RAL 7042

3.3.3. Care and Maintenance

Cleaning may be dependent on the paint system applied. A test is suggested in an inconspicuous area.

Emulsion Surfaces.

Moderate soiling can be removed using a warm detergent solution and a damp cloth. Wipe off with clean water and ensure the surface is dry.

Oil Based Surfaces.

Wash down with a warm detergent solution and wipe off with clean water and ensure the surface is dry.

Maintenance.

All surfaces can be revitalised with a further coat of the original paint.

Vinyl Wallcovering.

Can be washed with mild soapy water and rinsed off.

Textile Wallcovering.

See attached manufacturer’s info sheet if applicable.

3.3.4. Health & Safety

Refer to Manufactures Literature for safety data sheets.

3.3.5. Warranties

N/A

3.3.6. Recommended Spares

N/A

Back

3.3.7. Manufacturers Information

|

1. Description of Item |

Armstead Vinyl Matt |

|

Colour/Code/Ref/Batch number/ |

See Scope of works |

|

Location |

See Scope of works |

|

Manufacturer Contact details |

ICI Paints AkzoNobel, Wexham Road, Slough, Berkshire, SL2 5DS U.K

Tel: +44 (0) 8444 817 818 Fax: +44 (0) 8444 817 910 Web: www.icipaints.co.uk |

|

Manufacturers Literature |

|

2. Description of Item |

Bartoline Flexible Filler Decorators Caulk (Cartridge) Bartoline Flexible Filler (Tube) Bartoline White Spirit |

|

Colour/Code/Ref/Batch number/ |

See Scope of works |

|

Location |

See Scope of works |

|

Manufacturer Contact details |

Bartoline limited Barmston Close Beverley East Yorkshire HU17 0LW

Tel: 01482 678710 Fax: 01482 872606 Web: www.bartoline.co.uk |

|

Manufacturers Literature |

Click to view Bartoline Flexible Filler Decorators Caulk (Cartridge) Safety Data Sheet Click to view Bartoline Flexible Filler (Tube) Safety Data Sheet |

|

3. Description of Item |

Dulux High Gloss Safety Data Sheet |

|

Colour/Code/Ref/Batch number/ |

|

|

Location |

|

|

Manufacturer Contact details |

ICI Paints AkzoNobel, Wexham Road, Slough, Berkshire, SL2 5DS, U.K.

Tel: +44 (0) 333 222 70 70 Web: www.duluxtrade.co.uk |

|

Manufacturers Literature |

|

4. Description of Item |

Dulux Metalshield Satin Safety Data Sheet |

|

Colour/Code/Ref/Batch number/ |

|

|

Location |

|

|

Manufacturer Contact details |

ICI Paints AkzoNobel, Wexham Road, Slough, Berkshire, SL2 5DS, U.K.

Tel: +44 (0) 333 222 70 70 Web: www.duluxtrade.co.uk |

|

Manufacturers Literature |

|

5. Description of Item |

Dulux Satinwood Safety Data Sheet |

|

Colour/Code/Ref/Batch number/ |

|

|

Location |

|

|

Manufacturer Contact details |

ICI Paints AkzoNobel, Wexham Road, Slough, Berkshire, SL2 5DS, U.K.

Tel: +44 (0) 333 222 70 70 Web: www.duluxtrade.co.uk |

|

Manufacturers Literature |

|

6. Description of Item |

Dulux Vinyl Matt Emulsion Safety Data Sheet Dulux Vinyl Silk Safety Data Sheet |

|

Colour/Code/Ref/Batch number/ |

|

|

Location |

|

|

Manufacturer Contact details |

ICI Paints AkzoNobel, Wexham Road, Slough, Berkshire, SL2 5DS, U.K.

Tel: +44 (0) 333 222 70 70 Web: www.duluxtrade.co.uk |

|

Manufacturers Literature |

|

7. Description of Item |

Dulux Weathershield Smooth Masonry Paint Safety Data Sheet |

|

Colour/Code/Ref/Batch number/ |

|

|

Location |

|

|

Manufacturer Contact details |

ICI Paints AkzoNobel, Wexham Road, Slough, Berkshire, SL2 5DS, U.K.

Tel: +44 (0) 333 222 70 70 Web: www.duluxtrade.co.uk |

|

Manufacturers Literature |

|

8. Description of Item |

StoColor Silco Technical Data Sheet Stoplex W Technical Data Sheet StoPrim Fungal Technical data Sheet |

|

Colour/Code/Ref/Batch number/ |

|

|

Location |

|

|

Manufacturer Contact details |

Sto Ltd. Subsidiary 2 Gordon Avenue Hillington Park Glasgow G52 4TG

Tel: + 44 141 892 8000 Fax: + 44 141 404 9001 Email: info.uk@sto.com Web: http://www.sto.co.uk |

|

Manufacturers Literature |

Click to view StoColor Silco Technical Data Sheet |

3.3.8. Test and Commissioning Certificates

N/A

3.3.9. Record Drawings

N/A

3.4. Fabrication – Including Terrace Fence, Balustrade and Staircase Modification

3.4.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.4.2. Scope of Works

Company Name was responsible for the supply and installation of the metal terrace fencing, glass balustrade and modifications to the front and rear external escape staircases.

3.4.3. Operating Procedures

No Operation Involved

3.4.4. Care and Maintenance

Glass at downstairs Staircase

Can be cleaned with glass cleaner and soft nonabrasive cloth.

3.4.5. Residual Hazards & Risks

N/A

3.4.6. Health & Safety

N/A

3.4.7. Warranties

N/A

3.4.8. Recommended Spares

N/A

3.4.9. Manufacturers Information

N/A

3.4.10. Test and Commissioning Certificates

N/A

3.4.11. Record Drawings

N/A

3.5. Façade Cleaning

3.5.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.5.2. Scope of Works

Company Name were appointed by Company Name to:

Front of building:

• Doff clean the render from basement to roof edge (including balcony)

• Restoratively clean the powder coated aluminium window frames and doors

Rear of building:

• Doff clean the rear elevation.

• Doff clean the dwarf perimeter wall

• Restoratively clean the powder coated aluminium window frames and doors

• Restoratively clean the glazing

3.5.2.1. Description of Works

Window frames

Facades restored using See Brilliance restoration products: SBR-P/P and SBR-PCB. Products applied with white scotch, terri towel, polishing cloths.

Glazing

Glazing restored using See Brilliance restoration products: SBR-POW2. Products applied with white scotch, terri towel, polishing cloths.

Front render and rear elevations

Doff steam cleaned

3.5.2.2. Sample Photograph

Sample area of works were carried out prior to commencement of works.

3.5.3. Care and Maintenance

External frames

It is recommended that the frames are re-treated with the See Brilliance products SBR-P/P. This should be undertaken every 4 - 5 years, depending on the micro climate of the building and would be approximately 50% of the original restoration cost. See Brilliance will be happy to carry out a free health check.

Cleaning of the External windows

It is recommended that the glass is cleaned minimum of every 3 months

Use a mild solution of neutral detergent and water (1:20); with a squeegee and cloth.

3.5.4. Residual Hazards & Risks

No hazards were identified

3.5.5. Health & Safety

N/A

3.5.6. Warranties

N/A

3.5.7. Recommended Spares

N/A

3.5.8. Manufacturers Information

|

1. Description of Item |

Facade cleaner for coated surfaces |

|

Colour/Code/Ref/Batch number/ |

SBR-P/P |

|

Location |

|

|

Manufacturer Contact details |

See Brilliance Limited Unit M, Venture House Bone Lane Newbury Berkshire RG14 5SH

Tel: 01635 230888 Email: info@seebrilliance.com |

|

Manufacturers Literature |

|

2. Description of Item |

Pumice stone flour glass polish |

|

Colour/Code/Ref/Batch number/ |

SBR-PCB |

|

Location |

|

|

Manufacturer Contact details |

See Brilliance Limited Unit M, Venture House Bone Lane Newbury Berkshire RG14 5SH

Tel: 01635 230888 Email: info@seebrilliance.com |

|

Manufacturers Literature |

|

3. Description of Item |

Facade cleaner / preservative for coated Aluminium surfaces |

|

Colour/Code/Ref/Batch number/ |

SBR-POW2 |

|

Location |

|

|

Manufacturer Contact details |

See Brilliance Limited Unit M, Venture House Bone Lane Newbury Berkshire RG14 5SH

Tel: 01635 230888 Email: info@seebrilliance.com |

|

Manufacturers Literature |

3.5.9. Test and Commissioning Certificates

N/A

3.5.10. Record Drawings

N/A

3.6. Glazing including New Roof Light

3.6.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.6.2. Scope of Works

Company Name was contracted to carry out works as listed below:

1. Replacement of window frame and wedge gaskets

2. Replacement of defective friction stays

3. Replacement of defective /missing window handles

4. Servicing of all opening windows and doors

5. Replacement of defective double glazed units

6. Replacement of 1no dual pitched roof light

3.6.3. Care and Maintenance

Glazing and polyester powder framework should be cleaned as required using a mild detergent and no abrasive cloth. During cleaning the small plastic shoots between the transom caps to be clean of any dirt and debris on roof light.

3.6.4. Health & Safety

The roof light is not supplied in a man safe specification and as such a guard rail should always be in place to prevent occupants, falling against the glass

3.6.5. Warranties

2 Year defect liability of roof light installation, 1 year on chain actuators. 15 year defect liability on all paint, seals gaskets and frameworks

3.6.6. Recommended Spares

N/A

3.6.7. Manufacturers Information

|

1. Description of Item |

Rooflight |

|

Colour/Code/Ref/Batch number/ |

FW50+ |

|

Location |

|

|

Manufacturer Contact details |

Extrusion Supplied by Shueco

Manufactured and installed by Camb Glass |

|

Manufacturers Literature |

As per As Built’s Section 5.6.9 |

|

2. Description of Item |

Self-Adhesive Bubble Gasket |

|

Colour/Code/Ref/Batch number/ |

Acoustic bubble seal |

|

Location |

Multiple |

|

Manufacturer Contact details |

Reddiseals Furlong Business Centre, Berry Hill Industrial Estate, Droitwich WR9 9BG

|

|

Manufacturers Literature |

- |

|

3. Description of Item |

Wedge Gasket |

|

Colour/Code/Ref/Batch number/ |

Product Code - TW034 System - 3-4mm wedge Type - Aluminium Length - 225m Packaging - Tub Material - TPE Colour - Black Other - 3-4mm tear off |

|

Location |

|

|

Manufacturer Contact details |

Central Extrusions 7 Charlton Dr, Corngreaves Trading Estate, Cradley Heath B64 7BJ

|

|

Manufacturers Literature |

- |

|

4. Description of Item |

Glass |

|

Colour/Code/Ref/Batch number/ |

6mm clear float 12mm spacer 6mm clear float |

|

Location |

Multiple |

|

Manufacturer Contact details |

Cambs Glass Processing 6 Barnes Close Brandon, Suffolk IP27 0NY |

|

Manufacturers Literature |

N/A |

|

5. Description of Item |

Friction Stays |

|

Colour/Code/Ref/Batch number/ |

Heavy Duty Friction Hinge – upvc/timber 400mm (side hung) |

|

Location |

|

|

Manufacturer Contact details |

Securistyle Kingsmead Industrial Estate Princess Elizabeth Way Cheltenham Gloucestershire GL51 7RE |

|

Manufacturers Literature |

- |

|

6. Description of Item |

Window Handles |

|

Colour/Code/Ref/Batch number/ |

LH B195 RH B195 |

|

Location |

Multiple |

|

Manufacturer Contact details |

DG Supplyline Ltd 122-124 Prince Avenue Westcliff-on-Sea Essex SS0 0NW |

|

Manufacturers Literature |

- |

3.6.8. Test and Commissioning Certificates

N/A

3.6.9. Record Drawings

|

Drawing Number |

Drawing Title |

Rev |

Issue Date |

Checked |

|

001 |

C |

03/05/16 |

AE |

|

|

002 |

C |

03/05/16 |

AE |

|

|

003 |

C |

03/05/16 |

AE |

|

|

004 |

C |

03/05/16 |

AE |

3.7. Mansafe System

3.7.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.7.2. Introduction

These User Instructions contain important information regarding the Height Safety System/s, which have been installed for use at these premises. These systems have been designed to provide safe access and to protect against falls from height. Specific activities identified in a risk assessment for the building such as: rooflight cleaning, gutter cleaning, roof access, maintenance of services, roof inspections etc. are covered by the system/s, full details are provided in Section 3: Site Specific Information.

Safety systems can fall into three categories, ‘Collective Protection’ systems, ‘Fall Restraint’ systems or ‘Fall Arrest’ systems.

Collective Protection Systems such as guard-rails provide a safe zone inside the boundary of the guard-rail where any user can work safely without the need for additional height safety Personal Protective Equipment (PPE). There is no specific requirement for user training but personnel must be aware of the design principals of the system and any limitations to its effectiveness.

Fall Restraint Systems are designed to restrict the degree of travel and prevent the user reaching the point where a fall risk is present. Specific user PPE is required to ensure correct use of these systems and prevent possible injury. All system users should also undergoing training in the correct use of the system and its related PPE.

Fall Arrest Systems are designed to minimise the risk of injury caused by a fall should it occur. Again specific user PPE and training are required to ensure the safe and correct use of these systems.

The equipment and systems are designed for a specific application and are unique to it; they should not be moved, transferred, altered or amended in any way.

Warning:

These Safety Systems are required to be inspected and certified on a periodic basis by a competent person as laid down in the relevant British Standards.

The system details have automatically been entered into HCL Safety database to enable us to provide you with a reminder when the system is due for re-certification.

3.7.3. Scope of Works

System Details

· Latchways® Free Standing Guard-rail

Installed by HCL Safety Ltd utilising components designed and manufactured by Latchways plc.

Description & Compliance Details

The system provides collective protection against falls and creates a safe zone within which users can operate. It is designed and installed by HCL Safety utilising components sourced from a number of manufacturers.

Latchways® Free Standing Guard-rail is a free-standing, permanent guard-rail system for areas requiring access for maintenance or other temporary or short term activities. It is not designed or intended to act as a barrier or guard-rail to protect general occupants accessing the area for everyday use.

The system relies on the cantilever principle to prevent overturning and friction between the base plates and the roof surface to resist against sliding. The system consists of aluminium tube uprights and cast galvanised fittings. The steel base plates act as a counterweight, these should never be moved or repositioned except by HCL Safety Ltd or persons authorised by them.

This system complies with the following standards:

· Recommendations in HSE Special Inspectors Report Nº15: 1987

· Proposed requirements BS EN 13374: 1998: Temporary Edge Protection Systems

3.7.4. Operating Instructions

Key Points

· The system has been designed as a complete entity with the total stability reliant on the interaction between various sections. Under no circumstances should alterations be made to the system, or uprights be repositioned or removed.

· The maximum spacing of uprights is 2 metres.

· Personnel carrying out activities in close proximity to the guard-rail should ensure that they do not reduce the effective height of the protection below 1100mm e.g. by working on ladders or on top of plant, without taking additional precautions to prevent the risk of falls over the top of the guard-rail. All work requiring personnel to carry out activities at an elevated position must first be referred to a competent person responsible for the provision of safe working access.

· Under no circumstances must the Latchways® Free Standing Guard-rail system be used for attachment of PPE or other equipment. Any attachment will reduce the effectiveness of the system and failure to observe this requirement could lead to serious injury or fatalities.

· If in doubt refer to HCL Safety Ltd quoting the reference at the top of the page for further guidance regarding the use of the system.

Access

Access to the safe zone created by the Latchways® Free Standing Guard-rail system should be strictly controlled and limited to the designated entry/exit points. No more than 2 operatives should work in an area adjacent to a 6 metre run of guard-rail at any time.

3.7.5. Care and Maintenance

Periodic review of the Latchways® Free Standing Guard-rail system is required to check tightness of fittings and completeness of galvanised finish to all components.

Tightness of Fittings

The effectiveness of all guard-rail systems requires that all fittings are fully tightened. Prior to every work session within the safe area created by the Latchways® Free Standing Guard-rail a visual inspection of the complete system should be carried out to determine whether there are any obvious loose fittings. If there is any doubt, a simple push/pull movement would indicate a particularly loose fitting. Care should be taken to ensure the operative is located in a safe area when carrying out this test and that there is no risk of personnel or equipment falling should the guard-rail element become detached.

Annually the complete Latchways® Free Standing Guard-rail system should undergo a physical check to ensure that all fittings are fully tightened.

In all circumstances please refer to HCL Safety Ltd for further information.

Periodic Examination Record – VersiRail® System/s

Equipment Details

|

Type: Latchways VersiRail® |

Location: Roof |

|

Issue Date: |

Installation Date: 20th April 2016 |

|

Premises: 30-31 Newman Street |

Designer: |

|

Contract No: BREN2862 |

Examination Interval: 12 months |

|

Date |

Issue identified |

Action taken |

Action taken by Print name |

Action taken by Signature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.7.6. Health & Safety

Before entering a fall risk area, the User must fully familiarise them self with the requirements and information contained within this manual to ensure their own safety. If they have any doubts or questions these should be raised with Site Management and the system should not be used.

The equipment is designed to prevent or minimise the risk of injury from falls, but incorrect use through failure to adhere to these instructions could result in serious consequences even death. It is important that Site Management ensure that the User is familiar with the purpose and operation of this equipment. It is recommended that all System Users are fully trained in the correct use of the safety systems and equipment in the work place. HCL Safety Ltd is happy to carry out on-site training if required. This service will involve additional charges.

Key Points

· The system must be subject to periodic examination by a competent person approved by HCL Safety Limited. It must not be used if it has not been serviced within the last twelve months. Site Management and the User must satisfy themselves that each system has a valid certificate before each occasion of use.

· A warning notice defining that a fall hazard is present should be displayed close to each point of entry to the system.

· The User should always carry out a visual inspection of the system prior to and during initial use.

· No system should be used if a Prohibition Notice is in place or if a work permit has been withdrawn.

· Users having concern over their fitness for working at height should consult their doctor. Conditions of concern include; fainting, dizziness, fits, blackouts, high blood pressure, circulatory/ heart problems, muscular/ skeletal problems, recurring injuries, breathing difficulties, undergoing medical treatment, medication, consumption of alcohol in preceding 24 hour period. This list is not exhaustive.

3.7.7. Warranties

N/A

3.7.8. Recommended Spares

N/A

3.7.9. Manufacturers Information

|

1. Description of Item |

VersiRail Guard rail |

|

Colour/Code/Ref/Batch number/ |

BREN2862 |

|

Location |

Roof |

|

Manufacturer Contact details |

Latchways plc Hopton Park Devizes Wiltshire SN10 2JP

Tel: 01380 732 700 Fax: 01380 732 701 E-Mail: info@latchways.com |

|

Manufacturers Literature |

- |

3.7.10. Test and Commissioning Certificates

|

Description |

Certificate |

|

Examination and Testing Certificate |

3.7.11. Record Drawings

N/A

3.8. Manhole Covers and Frames

3.8.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.8.2. Scope of Works

To carry out replacement of existing man hole covers and frames

3.8.3. Care and Maintenance

N/A

3.8.4. Health & Safety

N/A

3.8.5. Warranties

N/A

3.8.6. Recommended Spares

N/A

3.8.7. Manufacturers Information

|

1. Description of Item |

Recessed Tray |

|

Colour/Code/Ref/Batch number/ |

Double Seal Locking |

|

Location |

|

|

Supplier Contact details |

Manhole Covers Limited Airfield Industrial Estate, Cheddington Lane, Long Marston, Bucks, HP23 4QR

Tel: 01296 668850 Fax: 01296 668080 Email: sales@manholecovers.co.uk |

|

Manufacturers Literature |

3.8.8. Test and Commissioning Certificates

N/A

3.8.9. Record Drawings

N/A

3.9. Raised Flooring

3.9.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.9.2. Scope of Works

Area of Works – Basement – 5th floor main areas

Package – K41 – Raised Access Floors

Supply and install Permaflor Medium Grade raised access floor complete with pedestals, adhesive fixed to concrete subfloor.

3.9.3. Care and Maintenance

3.9.3.1. Handling

It is important that panels are removed and replaced by lifting and lowering in the horizontal plane. The panel edges are shaped to facilitate this removal and replacement.

The lifting of panels by a "hinging" action that is raising/pivoting from one side should be avoided if possible. However the system is designed so that lifting in this way does not damage components.

A correct panel lifting device should always be employed; the use of screwdrivers, chisels etc. to prise panels up will result in damage to the panel edge and any surface covering and must not be used in any circumstance.

According to the type of surface material, it may be found that withdrawing and repositioning panels is accomplished more easily by the use of two lifting devices, which allows the weight and balance to be more easily controlled. Extra panel lifting devices are available directly from RMF Installations and Services Ltd.

To lift panels, ensure panel surface is clean and that lifting device is operating correctly. Position lifter, lift panel and turn through 45° until resting on adjacent four panels. Remove lifter from panel surface and lift manually to place aside. Reverse this operation to replace the panel.

Each panel should locate without the use of force into its proper position. If it fails to do so, remove it and investigate the reason. DONOTFORCEITINTOPOSITION!!

Panels which abut structural features or fixed elements may not be removable. In the event that they are, such panels will have been scribed and cut to fit and must always be replaced in the same position.

3.9.3.2. Safety

Panels should not be removed and left out of position unnecessarily leaving the floor void exposed.

Panels should be lifted in rows rather than blocks (see diagrams below)

When panels have been removed in rows, it is advisable to leave single panels in position at approximately 2.4m centres to maintain the floor grid and stability.

With panels out of position, extra care must be taken, especially if equipment is being moved.

Never leave pedestals isolated, as they are liable to displacement or damage.

Working in rows overcomes this problem.

When work in the cavity is under-way, hazard barriers and suitable warning notices should always be displayed.

![]()

Lift Panel Keep one panel located every 2.4 lm Incorrect lifting of panels

![]()

Lift panels in alternate rows Incorrect lifting of panels

*BEWARE LIVE CABLES. TAKE CARE TO AVOID DAMAGE TO SERVICES.

Cordon off or otherwise protect cut-outs in panels. Identify with hazard tape. Before re-locating panels, ensure that stringers (if any) are in place, the pedestals are firmly fixed to the sub floor, and are upright.

Check that pedestal caps are correctly aligned and free from dust and debris. See that any electrical continuity devices are properly in position.

Damaged or worn surfaces should be considered for repair or replacement without Delay especially if they are creating a trip hazard.

3.9.3.3. Maintenance

The amount maintenance likely to be required will depend on function and the type and volume of traffic across the floor.

Check the substructure whenever the opportunity presents itself.

To prevent small problems becoming serious, adjustments and repairs should be actioned as quickly as possible. The remedy may be as fast and simple as changing standard panels in high traffic areas with others which are in more remote positions.

Should a panel show any sign of instability, investigate and rectify because there will certainly be a reason which should be exposed.

3.9.3.4. Cleaning

a) The Floor Void

Whenever panels have been out of position for access, the cavity should be checked for cleanliness. Vacuuming is the most appropriate method for removing dust and small debris.

If a floor sealer has been employed previously, any cracking or flaking should be noted so that repair work can be scheduled.

At all times utmost care should be taken as there are likely to be live cables (415v) and expensive fibre optics in the floor void.

b) Bare Steel Panels

Keep clean by sweeping or vacuuming. Surface of bare steel panel maybe wiped over with a damp cloth.

Care should be taken to avoid use of excessive amounts of water.

c) Vinyl Covered Panels

Vinyl Covering, which has been bonded to access floor panels, is likely to have static control Properties.

Do not impair these by using sealing compounds, polishes etc.

Remove loose dirt and dust by sweeping and / or vacuuming.

DO NOT WASH.

The recommended method for maintaining a good appearance on the floor surface is frequent dry rotary buffing.

The floor covering may become indented or lined by the wheels, castors or feet of static or moving objects.

It is strongly recommended to protect against damage by overlaying the floor with a suitable sheet material when equipment is being manoeuvred.

• For any additional raised floor materials or modifications and adjustments to your existing raised access floor system, please contact us directly, where one of our experienced team will be pleased to assist you further.

3.9.4. Health & Safety

N/A

3.9.5. Warranties

N/A

3.9.6. Recommended Spares

N/A

3.9.7. Manufacturers Information

|

1. Description of Item |

Raised Floor |

|

Colour/Code/Ref/Batch number/ |

RMF – BGM600 Steel Encapsulated Panel |

|

Location |

Basement – 5th floor main areas |

|

Manufacturer Contact details |

RMF Installations Hangar One Harbury Lane Leamington Spa CV33 9SA

Tel: 01926 425289 Fax: 01926 451562 Email: info@rmf-services.co.uk |

|

Manufacturers Literature |

3.9.8. Test and Commissioning Certificates

N/A

3.9.9. Record Drawings

N/A

3.10. Resin Flooring

3.10.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.10.2. Scope of Works

Company Name was contracted to carry out works comprising supply and installation of latex flooring to Basement Bike Storage Floor.

3.10.3. Care and Maintenance

Sweep or Scrub & Wet Vacuum to remove soiling

3.10.4. Health & Safety

N/A

3.10.5. Warranties

N/A

3.10.6. Recommended Spares

N/A

3.10.7. Manufacturers Information

|

1. Description of Item |

Epoxy Flex PH Coating |

|

Colour/Code/Ref/Batch number/ |

RAL 7001 |

|

Location |

Basement Bike Storage |

|

Manufacturer Contact details |

Remmers (uk) Ltd Unit B1 Fleming Centre Crawley West Sussex RH10 9NN

Tel: +44 (0) 1293 594 010 Fax: +44 (0) 1293 594 037 Email: sales@remmers.co.uk |

|

Manufacturers Literature |

3.10.8. Test and Commissioning Certificates

N/A

3.10.9. Record Drawings

N/A

3.11. Shop Front

3.11.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.11.2. Scope of Works

This section of the manual covers the glazing works that were included in the works at ABC Project, Company Name commenced their portion of the on site works April 2016 and completed their portion of the works in May 2016

The basic design data was as Company Name and adpated by Company Name

Works Description

Manufacture and installation into prepared ground:

1 no 3955mm x 2100mm - outer frame

1 no 1317mm x 2732mm - outer frame and single mullion

100mm x 50mm Satin Sainless Steel Box section grade 304 with 25mm/25mm beading internal and external - glazed with 30/30 FR external glass units

16mm Contraflam 30 /16mm black warm edge Argon gas fill/6mm planitherm toughend

1 no 1100mm x 2732mm Aluminium door, frame and glazed over panel

All exposed surfaces clad and wrapped with 1.2mm Satin stainless steel sheet grade 304 - glazed with standard double glazed units

6mm clear toughened/16mm balc warm edge Argon gas fill/6mm planitherm tgh

2 no standard key/key locks 1000mm c-c Cranked D-handle x 19mm tube dia concealed door closer NHO

Removal of existing glass, frames and door set and disposal

Builders work to prepare structural openings to accept new will be completed by Area²

3.11.3. Care and Maintenance

3.11.3.1. General Notes to Maintenance Contractor

Risk Assessment

A risk assessment must be carried out, the form completed and signed prior to commencing work. Control measures must be taken if dictated by the result of a risk assessment. Due regard must also be given to the Residual Hazards detailed in the appropriate section of the Health & Safety file.

Warning

Before commencing maintenance work on any items of plant ensure that the associated supplies have been isolated and locked off and that control and ancillary circuits have been made dead.

Manufacturers Literature

These general maintenance guidance notes are supplemented by particular manufacturer's recommendations:- Refer to companion manufacturers literature documents in Section 5.3.7.

Health & Safety

All work must be carried out in accordance with the Health & Safety at Work Act 1974 and associated legislation and HSE Guideline Publications

Daily / Weekly Tasks

Routine Daily/Weekly inspections and tasks must form part of the maintenance routine and actions arising must be dealt with

Specialist Equipment

It is recommended that a Maintenance Contract is place for any specialist equipment

3.11.3.2. Maintenance Schedule

|

Item |

Frequency of Maintenance |

Maintenance Tasks |

|

Glazing |

Monthly |

Wash as per cleaning instructions - Data Sheet attached |

|

Door and Frames |

Monthly |

Wash with warm soapy water using a soft cloth - do not use abrasive cloths - dry thoroughly |

3.11.3.3. Cleaning Information

|

Item |

Frequency of Maintenance |

Maintenance Tasks |

|

Glazing |

Monthly |

Wash as often as possible with clean water and a chamois leather, scrim or squeegee, and dry off. The occasional application of a proprietary window cleaner or polish can be beneficial providing it does not contain ammonia. |

|

Door and Frames |

Monthly |

Wash as often as possible with clean water and chamois leather, and dry off. |

3.11.4. Health & Safety

All parties involved in the Operation and Maintenance of the Building Services Installation must comply with the current requirements of the Health & Safety at Work Act 1999. Also with any other relevant statutory codes of Practise that may apply. The HSW Act (hereafter referred to as "The Act") established Health and Safety Commission (HSC) and the Health and Safety Executive (HSE)

Objective of the Act:

a) Securing the Health, safety and welfare of people at work

b) Protecting people other than those at work against risk to their health and safety arising out of work activities

c) Controlling the keeping and use of explosive or highly flammable or otherwise dangerous substances, and generally preventing people from unlawfully having and using substances

d) Controlling the release into the atmosphere of noxious or offensive substances from prescribed premises

Duties under the Act

Are imposed on everyone concerned with work activities, ranging from employers, self employed and employees, to manufacturers, designers, suppliers and importers of materials for use at work, and even extending to members of the public. The duties are imposed on both individuals and on corporations, companies, partnerships, local authorities, nationalised industries etc.

"Absolute" Duties

Some duties imposed by the Act and related statutory Regulations are said to be "absolute" and must be complied with, regardless of cost or any other consideration. Other duties are qualified by the words "so far as reasonably practicable", "so far as practicable" or "best practicable means" mean that the degree of risk for a particular activity or environment can be weighed against the time, trouble, costs and physical difficulty of taking measures to avoid the task.

Modification and Disposal Instructions

Procedures should be provided for the safe disposal of, or recycling of equipment, including packaging, insulation, fluid and lamps. Where relevant, this should be in accordance with specific regulations such as the Control of Substances Hazardous to Health (COSHH)

Hazardous Materials

None

Schedule of Residual Hazards

N/A

Schedule of Associated Health & Safety Information/Data Sheets

N/A

3.11.5. Warranties

|

Description |

Warranty Ref |

Start Date |

Expiry Date |

Contact details |

|

Contract Warranty |

12 Month Contract |

01.06.16 |

31.05.17 |

Area² Ltd |

3.11.6. Recommended Spares

N/A

3.11.7. Manufacturers Information

|

1. Description of Item |

Glazing Units |

|

Colour/Code/Ref/Batch number/ |

SGG PLANITHERM® TOTAL + PYROBEL FIRE RESISTING GLASS |

|

Manufacturer Contact details |

London Archtectural Glass Unit 5 Arkwright Road Slough, SL3 0HL

Tel: +44(0)1753 313 123 Email: info@lag.glass |

|

Manufacturers Literature |

|

2. Description of Item |

Glazing Frame |

|

Manufacturer Contact details |

Protosheet Engineering Ltd 73 Swaisland Drive Crayford Kent DA1 4HY

Tel: +44 (0)1322 550545 Fax: +44 (0)1322 555719 Email: info@protosheet.co.uk |

|

Manufacturers Literature |

- |

|

3. Description of Item |

Stainless Steel Letter Plate |

|

Manufacturer Contact details |

Savekers Solutions Limited Norton Street Radnor Street Corner Birmingham B18 5RQ

Tel: +44 (0)121 507 0300 Fax: +44 (0)121 554 1204 Email: info@savekerssolutions.com |

|

Manufacturers Literature |

- |

|

4. Description of Item |

Door Sets, closers, handles and electronic door release |

|

Manufacturer Contact details |

London Shopfitters Ltd Unit 6, Blackwater Close, Marsh Way, Rainham, Essex. RM13 8UA.

Tel: 01708 552225, Fax: 01708 557567 |

|

Manufacturers Literature |

- |

3.11.8. Test and Commissioning Certificates

See Manufactures Literature for product certification.

|

Description |

Certificate |

|

Certificate of Conformity |

3.11.9. Record Drawings

|

Drawing Number |

Drawing Title |

Rev |

Issue Date |

Checked |

|

23332/FR-001 |

AB |

23/03/2016 |

- |

|

|

23332/FED-001 |

AB |

23/03/2016 |

- |

|

|

23332/GA-001 |

B |

30/03/2016 |

- |

|

|

23332/GA-002 |

B |

30/03/2016 |

- |

|

|

23332/SD-001 |

B |

30/03/2016 |

- |

3.12. Signage

3.12.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.12.2. Scope of Works

Company Name was responsible for supply the Light Box at ABC Project

Material: Brushed stainless steel, opal acrylic panel, LED lights

3.12.3. Care and Maintenance

1. Care must be taken when cleaning, use soft style sponge or water on soft cotton cloth.(Avoid getting any Abrasive Cleaner or solvent on vinyl where possible)

2. Do not use any type of Rubber Squeegee on side of acrylic that vinyl is applied, as it may scratch surface or damage edges.

3. Acrylic panel is removed by side trim being removed, it is advised two people undertake this procedure to avoid any damage to the panel.

4. Any electrical works, to the transformer or replacement of led lights should be done by a qualified electrician only.

3.12.4. Health & Safety

N/A

3.12.5. Warranties

N/A

3.12.6. Recommended Spares

N/A

3.12.7. Manufacturers Information

|

1. Description of Item |

Light Box |

|

Colour/Code/Ref/Batch number/ |

|

|

Location |

|

|

Manufacturer Contact details |

Aztec Group (UK) Ltd Unit E Eskdale Road, Uxbridge, Middlesex, UB8 2RT

Alan Jones T: 01895 520660 M:07974 212146 |

|

Manufacturers Literature |

Contact Manufacturer for further information |

3.12.8. Test and Commissioning Certificates

N/A

3.12.9. Record Drawings

|

Drawing Number |

Drawing Title |

Rev |

Issue Date |

Checked |

|

5269-30-0-PE |

- |

Feb 2016 |

- |

3.13. Walls and Ceilings

3.13.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.13.2. Scope of Works

Company Name was responsible for the following works:

3.13.2.1. Partitions to Main Area and WCs and Doors

100mm full height stud partitioning - Taped and Jointed 48mm vertical metal studs and top and bottom channels mechanically fixed into slab floor and below the soffit. Partition faced either side with 2no layers of 12.5mm moisture resistant tapered edged Gyproc wallboard with all joints to be taped and filled to receive decoration. Inner skin of 12mm plywood to allow wall mounting of shelves etc.

Doorsets

Standard height single door sets including a solid core Ply for painting door hung within a painted door frame. Door furniture satin stainless steel round bar levers on rose, full case latch and floor door stops. Doors 838mm wide.

Standard height single door sets a comprising of a solid core Polyrey Laminate Maryland Foncé M003 door hung within a painted door frame. Door furniture will be satin stainless steel round bar levers on rose, full case latch and floor door stops. Doors 838mm wide. With indicator bolts if required.

FD60S External grade steel door and frame located between service areas. 1.2mm M2M+ single door RH hinge outward opening, structural opening (TBC) 900mm wide x 2000mm high. 90mm frame. Fitted with lever latch handle either side and finished in RAL 9010. Vision panel 254mm x 1524mm (Firelite 5mm, glass size 227mm x 1497mm

FD60S External grade steel door and frame located between escape staircase and service area. 1.2mm M2M+ single door LH hinge outward opening, structural opening (TBC) 900mm wide x 2000mm high. 90mm frame. Fitted with push bar on staircase side and lever latch internally. Finished in RAL 9010. No vision panel allowed for.

New FD30s Fire Compartment Door - 1524mm x 152mm half hour fire rated clear glass vision panels doors B.03 & B.12

FD30S intumescent and smoke seal strips. Door number 0.04 New floor spring, flush pull and fire exit sign.

1524mm x 152mm 6.4mm clear laminate glass vision panels.

Satin stainless steel door closer to the new doors, doors that require self-closing.

3.13.2.2. Suspended Ceilings

Single skin MF moisture resistant plasterboard ceiling on standard metal framework including tape and jointing ready for decoration by others. These ceilings are to the Basement shower/wc block.

Supply and install single skin MF plasterboard ceiling on standard metal framework including tape and jointing ready for decoration by others. These ceilings are to the lobbies and WC's in the rest of the building as indicated on the marked up drawing

As above but for sloping bulkheads directly above the stairs only

Metal faced beaded ceiling access panels within the new MF ceilings only. ALLOWED FOR 600 X 600

3.13.2.3. Additional Items

Supply only benches to shower and WC areas with Oak slats, 3 no 900mm and 3 no 600mm

3.13.3. Care and Maintenance

Please refer to Manufacturers Literature

3.13.4. Health & Safety

N/A

3.13.5. Warranties

N/A

3.13.6. Recommended Spares

N/A

3.13.7. Manufacturers Information

|

1. Description of Item |

Wall Insulation |

|

Colour/Code/Ref/Batch number/ |

GypLyner universal |

|

Location |

|

|

Manufacturer Contact details |

British Gypsum East Leake Loughborough Leicestershire LE12 6HX

Tel: 0844 800 1991 Fax: 0844 561 8816 |

|

Manufacturers Literature |

|

2. Description of Item |

Partitions |

|

Colour/Code/Ref/Batch number/ |

Komfire 100 |

|

Location |

|

|

Manufacturer Contact details |

Unit 1 The Hub Nobel Way off Witton Road Birmingham B6 7ES

Tel: +44 (0)121 332 2400 Email headoffice@komfort.com |

|

Manufacturers Literature |

|

3. Description of Item |

Plasterboard Ceilings |

|

Colour/Code/Ref/Batch number/ |

Casoline MF System |

|

Location |

|

|

Manufacturer Contact details |

British Gypsum Head Office Gotham Road East Leake Loughborough Leicestershire LE12 6HX

T: 0115 945 1000 |

|

Manufacturers Literature |

|

4. Description of Item |

Timber Doors and Laminated Doors |

|

Colour/Code/Ref/Batch number/ |

Polyrey Caviar CO11 Doors |

|

Location |

|

|

Manufacturer Contact details |

Forza Doors Units 24 A & C Star Road, Partridge Green, Horsham RH13 8RA

Tel:01403 71112 |

|

Manufacturers Literature |

|

5. Description of Item |

Steel Lined Doors |

|

Colour/Code/Ref/Batch number/ |

G15 Doors |

|

Location |

|

|

Manufacturer Contact details |

Door Technik Moor Lane, Thorpe on the Hill, Lincoln, LN6 9BW

Tel : 01522 693522 |

|

Manufacturers Literature |

|

6. Description of Item |

Shower Bench |

|

Colour/Code/Ref/Batch number/ |

B90 and B60 Benches in Grey |

|

Location |

|

|

Manufacturer Contact details |

C S Storage Ltd 1a Roundhouse Court South Rings Business Park Preston Lancashire PR5 6DA

Tel: +44 (0)1772 322634 Fax: +44 (0)1772 696581 e-mail: sales@csstorage.co.uk |

|

Manufacturers Literature |

|

7. Description of Item |

Ironmongery |

|

Colour/Code/Ref/Batch number/ |

WP295S SSS heavy duty o/h door closer 2-5, c/w SR Cov. 561.SES Briton panic crash bar W776S-HD SSS lever handle on rose - sprung - screw on W860S SSS Cylindrical floor door stop heavy duty W7872 SSS Designer robe hook c/w rose W705S SSS disabled bathroom turn & release W312ERSP 76mm SSS E*S bathroom sashlock heavy W781S 76mm Dia SSS FIRE DOOR KEEP SHUT Sign W783S 76mm dia SSS MALE sign W797S 76mm dia SSS UNISEX sign W784S 76mm dia SSS FEMALE sign W785S 76mm dia SSS DISABLED sign W78299S 76mm dia SSS MOP & BUCKET sign W8042S 800x150mm SSS kickplate d/csk W8045S 1000 x 150mm SSS kickplate d/csk |

|

Location |

|

|

Manufacturer Contact details |

Welling Architectural Ironmongery Unit R1 Bourton Industrial Park Bourton-On-The-Water Gloucestershire GL56 2HQ

Tel 01451 824 110| Fax 01451 821 499| Email sales@wellinguk.com |

|

Manufacturers Literature |

3.13.8. Test and Commissioning Certificates

N/A

3.13.9. Record Drawings

N/A

3.14. Washrooms

3.14.1. Contractor

Company Name

1st line of address

2nd line of address

Town

postcode

Name Here

T: 00000 000 000

F: 11111 111 111

M: 22222 222 222

3.14.2. Scope of Works

Company Name were responsible for the supply and installation of the following:

3.14.2.1. Glass Panels

Back painted glass to WC’s

Splashbacks to basins

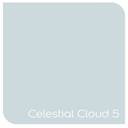

Dulux Colour

Celestial Cloud 5

70BG68/056

3.14.2.2. Solid Surface

Vanity Tops

Male & Female WCs

Basement Vanity Top

HI-MACS® VB02 Cima

All other Vanity Tops

HI-MACS® T17 Andromeda

3.14.2.3. Tiles

Reception Area – Flooring and Skirting

Solus Ceramics

Travertine 1 - Abyss, Natural

Porcelain tiles

3SCT0031

600 x 600 x 9.5mm &

Finish - Natural

(Grey grouting ref tbc)

Levels G - 5 WC – Flooring and Skirting

Solus Ceramics

Travertine 1 - Abyss, Natural

Porcelain tiles

3SCT0031

300 x 300 x 9.5mm &

300 x 100mm x 9.5mm skirting

Finish - Natural

(Grey grouting ref tbc)

Basement Shower Room & Toilet Areas

(Flooring Type C)

Solus Ceramics

Circular Mosaics

Range - Capital

Colour - Lamarck

Finish - Matt unglazed

19mm diameter x 5mm

(Cement Grey grout

Mapei 113)

3.14.2.4. Sanitaryware

|

WC Pan: |

222509 Duravit Starck 3 Wall Mounted White |

|

Seat/Cover: |

006389 Duravit Soft Close White |

|

WC Frame & Cistern: |

111.384.00.5 Geberit Duofix 112CM WC Frame |

|

Flush Plate: |

115.778.KH.1 Geberit Flush Plate Sigma20 Dual Flush Chrome |

|

Basin Tap: |

Grohe 71071000 Logis Single Lever Basin Mixer 70 Without Waste Set |

|

Wash Hand Basin: |

070350 Duravit Vero Basin White |

|

Shower Head & Arm: |

Grohe 28232000 Euphoria Cosmopolitan 160 - Fitted with Grohe 28541000 Shower Arm |

|

Shower TSV & Installation Box: |

Hans Grohe 15701000 Ecostat S Thermostatic Mixer for concealed installation with shut-off valve - fitted with Hans Grohe 01800180 I Box |

|

Doc M: |

Concealed Installation with Shut-Off Valve - Fitted with Hans Grohe 01800180 I Box |

3.14.2.5. Washroom Accessories

BC7504 Dolphin SSS Prestige Toilet Brush set

BC270 Dolphin SSS Toilet Roll Holder

BC402 Dolphin SSS Rob Hook

3.14.3. Care and Maintenance

Click to view Laminates Maintenance Manual

Click to view Corian Care and Maintenance

Click to view Cleaning and Maintenance of Tiles

Click to view Cleaning Sanitaryware

Click to view Cleaning Instructions – Taps

Click to view Grohe Tap Care Instructions

3.14.4. Health & Safety

Click to view Health & Safety Policy

3.14.5. Warranties

HI-MACS® Solid Surface - 15 Years – Click to view

Solus Tiles - Click to view

Duravit - 5 Years – Click to view

Geberit - 1 Year

Grohe - 5 Years – Click to view

Hans Grohe - 5 Years – Click to view

Armitage Shanks Ceramics - Lifetime

Armitage Shanks Parts (including push button flush valves) - 5 Years

3.14.6. Recommended Spares

N/A

3.14.7. Manufacturers Information

|

1. Description of Item |

Glass Panels |

|

Colour/Code/Ref/Batch number/ |

Dulux Colour: Celestial Cloud 5 70BG68/056 |

|

Location |

Back painted glass to WCs Splashbacks to basins |

|

Supplier Contact details |

Stevens Services Unit C & D Highgrove Industrial Pk Quartremarine Road Portsmouth Hampshire PO3 5QQ

Tel: 023 9263 9447 |

|

Manufacturers Literature |

- |

|

2. Description of Item |

Solid Surface |

|

Colour/Code/Ref/Batch number/ |

Basement Vanity Top: HI-MACS® VB02 Cima All other Vanity Tops: HI-MACS® T17 Andromeda |

|

Location |

Vanity Tops: Male & Female WCs |

|

Supplier Contact details |

Stevens Services Unit C & D Highgrove Industrial Pk Quartremarine Road Portsmouth Hampshire PO3 5QQ

Tel: 023 9263 9447 |

|

Manufacturers Literature |

|

3. Description of Item |

Tiles |

|

Colour/Code/Ref/Batch number/ |

Travertine 1 - Abyss, Natural Porcelain Tiles 3SCT0031 600 x 600 x 9.5mm & Finish - Natural |

|

Location |

Reception Area – Flooring and Skirting |

|

Supplier Contact details |

Stevens Services Unit C & D Highgrove Industrial Pk Quartremarine Road Portsmouth Hampshire PO3 5QQ

Tel: 023 9263 9447 |

|

Manufacturers Literature |

|

4. Description of Item |

Tiles |

|

Colour/Code/Ref/Batch number/ |

Travertine 1 - Abyss, Natural Porcelain Tiles 3SCT0031 300 x 300 x 9.5mm & 300 x 100mm x 9.5mm skirting Finish - Natural |

|

Location |

Levels G - 5 WC – Flooring and Skirting |

|

Supplier Contact details |

Stevens Services Unit C & D Highgrove Industrial Pk Quartremarine Road Portsmouth Hampshire PO3 5QQ

Tel: 023 9263 9447 |

|

Manufacturers Literature |

|

5. Description of Item |

Tiles |

|

Colour/Code/Ref/Batch number/ |

Circular Mosaics Range - Capital Colour - Lamarck Finish - Matt unglazed 19mm diameter x 5mm |

|

Location |

Basement Shower Room & Toilet Areas (Flooring Type C) |

|

Supplier Contact details |